Diesel Technology

Get started today

About Diesel Technology

Our Diesel Technology Program is designed to prepare students to enter the diesel mechanic career field. This instruction gives an understanding of diesel equipment construction, theory of operation, and standard industry service, and repair procedures. This instruction not only provides knowledge to perform equipment repair and service but also develops skills necessary to diagnose malfunctions. Two of the most important skills that will be developed are problem solving and critical thinking.

What you’ll learn

- Diagnose and repair common malfunctions of the following systems:

- Diesel engine principles and operation, shop operation and tool/equipment usage

- Diesel engine – lubrication, cooling, fuel injection systems, mechanical systems, intake, and exhaust including turbo chargers

- Diesel engine troubleshooting, testing, repair, and rebuild

- Medium and heavy-duty truck and equipment; electrical/electronic systems

- Medium and heavy-duty vehicle braking systems, hydraulic and air brake systems

- Steering and suspension systems

- Drive train systems – including automatic, auto-shift, and manual transmissions; driveline and differentials

- Preventive maintenance inspections

- Basic hydraulics and hydraulic systems

- Heavy-duty HVAC systems

- Basic welding, oxy-acetylene, plasma, and metal fabrication

- PA State Cat 3 Inspection and Federal DOT Safety Inspection procedures

- Develop sound and safe diesel shop practice skills, including environmental protection.

- Develop good shop habits, including demonstrating a good attendance record, punctuality, a willingness to

work as a team, and a positive attitude toward lifelong learning. - Apply laws of physics/scientific principles to diesel equipment systems and components when performing in-shop testing exercises and diagnostic procedures.

- Record diagnostic testing data and reports using necessary mathematics; solve basic problems using algebra.

- Locate and interpret technical data represented in shop manuals, diagnostic charts, and wiring diagrams. This could be hard copy or electronically driven.

- Demonstrate appropriate diesel shop management practices, including student management, customer relations, shop procedures, and writing repair orders.

- Prepare to take and pass the ASE Medium and Heavy-Duty Truck test series after successful completion of this

program and one year of on-the-job experience. - Prepare to become a lifelong learner. The diesel equipment industry is very fast paced with technology changing daily. Technicians will be constantly upgrading their knowledge and skills. A solid fundamental base is crucial for building these skills.

Sample Job Titles

Bus Mechanic, Diesel Mechanic, Diesel Technician, Fleet Mechanic, General Repair Mechanic, Mechanic, Service Technician, Trailer Mechanic, Transit Mechanic, Truck Mechanic

Quick facts

Location

Thaddeus Stevens College Transportation Center

Type of program

Associate Degree

Job/Salary Outlook

See industry data

Length of program

2 years, 76 credits

Cost of program

$4,500/semester tuition

$3,000 – $3,500/semester housing

$1,850 – $2,335/semester meal plan

Tool List (PDF)

The outcomes speak for themselves

Graduates of this program work in the agriculture, trucking, and heavy construction industries.

100%

employment

$47.5K

med. salary

Program details

Courses

MODEL SCHEDULE FOR DIESEL TECHNOLOGY

Semester 1

- DETC 105 Diesel Shop Safety (1 credit)

- DETC 110 Diesel Service Fundamentals (3 credits)

- DETC 115 Diesel Engine, Electrical, and Drive Train Components and Systems Preventive Maintenance (3 credits)

- DETC 120 Diesel Vehicle Brake, Suspension & Steering, and Cab Components Systems Preventive Maintenance (2 credits)

- DETC 160 Basic Electricity (3 credits)

- CIS 111 Intro to Computers (3 credits)

- MATH 126 Technical Math I (3 credits)

Semester 2

- DETC 125 Diesel Fuel and Supply Systems (3 credits)

- DETC 150 Diesel Engine Technology (4 credits)

- DETC 155 Diesel Engine Lab (3 credits)

- DETC 165 Introduction to Hydraulics (3 credits)

- MATH 132 Elementary Geometry or Math 136 Technical Math II (3 credits)

- ENG 106 English Composition (3 credits)

Semester 3

- DETC 205 Diesel Engine Electronic Fuel Systems, Operation and Diagnostics (3 credits)

- DETC 210 Vehicle Electronic Operation, Diagnostics, and Troubleshooting (3 credits)

- DETC 215 Medium and Heavy-Duty Brake Systems (4 credits)

- DETC 220 Diesel Equipment HVAC (3 credits)

- ENG 216 Technical Report Writing or ENG 221 Public Speaking (3 credits)

- PHYS 106 Physics for Everyday Life (3 credits)

Semester 4

- DETC 250 Manual, Automatic/Autoshift Transmission (4 credits)

- DETC 255 Steering, Suspension, Alignment (3 credits)

- DETC 260 Basic Welding and Fabrication (3 credits)

- DETC 265 Diesel Equipment Drive Train (3 credits)

- General Studies Elective (3 credits)

- Humanities Elective (3 credits)

Additional General Education Requirements

- HEAL Elective HEAL 106 or HEAL 111 (1 credit)

Total Credits 76

Click here to download PDF version of Diesel Technology’s Curriculum

Faculty

Occupational Advisory Committee

The Occupational Advisory Committee (OAC) serves as a vital link between the Program of study and industry, ensuring that the program remains aligned with current workforce needs, technological advancements, and best practices in the field. Composed of employers, educators, and other community members, the committee provides guidance, feedback, and recommendations to enhance the curriculum, instructional methods, and student learning experiences.

Purpose and Responsibilities:

- Curriculum & Industry Alignment

- Workforce Readiness

- Student & Faculty Support

- Internship & Employment Connections

- Accreditation & Program Evaluation

- Facilities & Equipment Recommendations

By fostering a strong relationship between academia and industry, the OAC helps ensure that Thaddeus Stevens College programs maintain the highest standards in CTE (career and technical education).

- Mike Bresch, High Transit LLC

- Curtis Brubaker, Jr., Transteck, Inc.

- Duane Bushong, Arconic

- Randy Fetterolf, Cleveland Brothers Equipment Co., Inc.

- Daniel Frey, Lancaster County CTC

- Chad Goodsell, Cummins Sales & Service

- Nicholas Hertzler, Sauder Eggs

- Messicks

- James Jack, Kenworth of Pennsylvania

- Robert Jensen, Transteck Inc. Harrisburg and York

- Seth Keefer, Penske Truck Leasing

- Jordan Keller, Brubacher Excavating, Inc.

- Andy Kunselman, Hunter Truck – Peterbilt

- Andy McComsey, FleetPride Heavy Duty Parts & Service

- Frank Miller, Kenworth of Pennsylvania

- Dusty Moran, B.R. Kreider & Son, Inc.

- Steve Myers, South Central Transit Authority

- Jonathan Perez, Executive Coach

- Brad Plank, Trans Equipment Co., Inc.

- Tony Wiser, Kenworth of Pennsylvania

Essential Skills Learned

Tasks

- Inspect brake systems, steering mechanisms, wheel bearings, and other important parts to ensure that they are in proper operating condition.

- Use hand tools, such as screwdrivers, pliers, wrenches, pressure gauges, or precision instruments, as well as power tools, such as pneumatic wrenches, lathes, welding equipment, or jacks and hoists.

- Adjust and reline brakes, align wheels, tighten bolts and screws, and reassemble equipment.

- Examine and adjust protective guards, loose bolts, and specified safety devices.

- Perform routine maintenance such as changing oil, checking batteries, and lubricating equipment and machinery.

- Test drive trucks and buses to diagnose malfunctions or to ensure that they are working properly.

- Raise trucks, buses, and heavy parts or equipment using hydraulic jacks or hoists.

- Attach test instruments to equipment, and read dials and gauges to diagnose malfunctions.

- Rebuild gas or diesel engines.

- Inspect and verify dimensions and clearances of parts to ensure conformance to factory specifications.

- Inspect, test, and listen to defective equipment to diagnose malfunctions, using test instruments such as handheld computers, motor analyzers, chassis charts, or pressure gauges.

Tools used in this occupation

- Adjustable wide-mouth pliers — Water pump pliers

- Adjustable wrenches — Adjustable crescent wrenches

- Automotive honing machine — Hones

- Ball peen hammer — Ball peen hammers

- Battery chargers

- Blow torch — Acetylene torches; Cutting torches

Technology used in this occupation

- Analytical or scientific software — Cummins Insite; Engine diagnostic software

- Calendar and scheduling software — Scheduling software

- Computer-aided design CAD software — Autodesk AutoCAD; Dassault Systemes CATIA; Dassault Systemes SOLIDWORKS

- Computer-aided manufacturing CAM software

- Database user interface and query software — Database software

Knowledge

- Mechanical — Knowledge of machines and tools, including their designs, uses, repair, and maintenance.

- Transportation — Knowledge of principles and methods for moving people or goods by air, rail, sea, or road, including the relative costs and benefits.

- Customer and Personal Service — Knowledge of principles and processes for providing customer and personal services. This includes customer needs assessment, meeting quality standards for services, and evaluation of customer satisfaction.

- Public Safety and Security — Knowledge of relevant equipment, policies, procedures, and strategies to promote effective local, state, or national security operations for the protection of people, data, property, and institutions.

- English Language — Knowledge of the structure and content of the English language including the meaning and spelling of words, rules of composition, and grammar.

- Engineering and Technology — Knowledge of the practical application of engineering science and technology. This includes applying principles, techniques, procedures, and equipment to the design and production of various goods and services.

Skills

- Repairing — Repairing machines or systems using the needed tools.

- Troubleshooting — Determining causes of operating errors and deciding what to do about it.

- Operation and Control — Controlling operations of equipment or systems.

- Operation Monitoring — Watching gauges, dials, or other indicators to make sure a machine is working properly.

- Critical Thinking — Using logic and reasoning to identify the strengths and weaknesses of alternative solutions, conclusions, or approaches to problems.

- Equipment Maintenance — Performing routine maintenance on equipment and determining when and what kind of maintenance is needed.

- Quality Control Analysis — Conducting tests and inspections of products, services, or processes to evaluate quality or performance.

- Equipment Selection — Determining the kind of tools and equipment needed to do a job.

- Judgment and Decision Making — Considering the relative costs and benefits of potential actions to choose the most appropriate one.

- Speaking — Talking to others to convey information effectively.

- Complex Problem Solving — Identifying complex problems and reviewing related information to develop and evaluate options and implement solutions.

- Coordination — Adjusting actions in relation to others’ actions.

Abilities

- Near Vision — The ability to see details at close range (within a few feet of the observer).

- Finger Dexterity — The ability to make precisely coordinated movements of the fingers of one or both hands to grasp, manipulate, or assemble very small objects.

- Manual Dexterity — The ability to quickly move your hand, your hand together with your arm, or your two hands to grasp, manipulate, or assemble objects.

- Problem Sensitivity — The ability to tell when something is wrong or is likely to go wrong. It does not involve solving the problem, only recognizing there is a problem.

- Arm-Hand Steadiness — The ability to keep your hand and arm steady while moving your arm or while holding your arm and hand in one position.

- Control Precision — The ability to quickly and repeatedly adjust the controls of a machine or a vehicle to exact positions.

- Deductive Reasoning — The ability to apply general rules to specific problems to produce answers that make sense.

- Hearing Sensitivity — The ability to detect or tell the differences between sounds that vary in pitch and loudness.

- Multi-limb Coordination — The ability to coordinate two or more limbs (for example, two arms, two legs, or one leg and one arm) while sitting, standing, or lying down. It does not involve performing the activities while the whole body is in motion.

- Extent Flexibility — The ability to bend, stretch, twist, or reach with your body, arms, and/or legs.

- Inductive Reasoning — The ability to combine pieces of information to form general rules or conclusions (includes finding a relationship among seemingly unrelated events).

- Information Ordering — The ability to arrange things or actions in a certain order or pattern according to a specific rule or set of rules (e.g., patterns of numbers, letters, words, pictures, mathematical operations).

Work Activities

- Repairing and Maintaining Mechanical Equipment — Servicing, repairing, adjusting, and testing machines, devices, moving parts, and equipment that operate primarily on the basis of mechanical (not electronic) principles.

- Getting Information — Observing, receiving, and otherwise obtaining information from all relevant sources.

- Operating Vehicles, Mechanized Devices, or Equipment — Running, maneuvering, navigating, or driving vehicles or mechanized equipment, such as forklifts, passenger vehicles, aircraft, or watercraft.

- Inspecting Equipment, Structures, or Material — Inspecting equipment, structures, or materials to identify the cause of errors or other problems or defects.

- Evaluating Information to Determine Compliance with Standards — Using relevant information and individual judgment to determine whether events or processes comply with laws, regulations, or standards.

- Identifying Objects, Actions, and Events — Identifying information by categorizing, estimating, recognizing differences or similarities, and detecting changes in circumstances or events.

- Communicating with Supervisors, Peers, or Subordinates — Providing information to supervisors, co-workers, and subordinates by telephone, in written form, e-mail, or in person.

- Documenting/Recording Information — Entering, transcribing, recording, storing, or maintaining information in written or electronic/magnetic form.

- Making Decisions and Solving Problems — Analyzing information and evaluating results to choose the best solution and solve problems.

- Performing General Physical Activities — Performing physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling of materials.

Work Context

- Spend Time Using Your Hands to Handle, Control, or Feel Objects, Tools, or Controls — 90% responded “Continually or almost continually.”

- Wear Common Protective or Safety Equipment such as Safety Shoes, Glasses, Gloves, Hearing Protection, Hard Hats, or Life Jackets — 80% responded “Every day.”

- Exposed to Contaminants — 82% responded “Every day.”

- Outdoors, Exposed to Weather — 67% responded “Every day.”

- Face-to-Face Discussions — 73% responded “Every day.”

- In an Enclosed Vehicle or Equipment — 52% responded “Every day.”

- Telephone — 62% responded “Every day.”

- Sounds, Noise Levels Are Distracting or Uncomfortable — 74% responded “Every day.”

- Contact with Others — 49% responded “Contact with others most of the time.”

- Exposed to Hazardous Equipment — 71% responded “Every day.”

- Freedom to Make Decisions — 51% responded “Some freedom.”

- Structured versus Unstructured Work — 51% responded “A lot of freedom.”

Interests

Interest code: RC

- Realistic — Realistic occupations frequently involve work activities that include practical, hands-on problems, and solutions. They often deal with plants, animals, and real-world materials like wood, tools, and machinery. Many of the occupations require working outside and do not involve a lot of paperwork or working closely with others.

- Conventional — Conventional occupations frequently involve following set procedures and routines. These occupations can include working with data and details more than with ideas. Usually, there is a clear line of authority to follow.

Work Styles

- Adaptability/Flexibility — Job requires being open to change (positive or negative) and to considerable variety in the workplace.

- Attention to Detail — Job requires being careful about detail and thorough in completing work tasks.

- Dependability — Job requires being reliable, responsible, and dependable, and fulfilling obligations.

- Stress Tolerance — Job requires accepting criticism and dealing calmly and effectively with high-stress situations.

- Analytical Thinking — Job requires analyzing information and using logic to address work-related issues and problems.

- Integrity — Job requires being honest and ethical.

- Initiative — Job requires a willingness to take on responsibilities and challenges.

- Persistence — Job requires persistence in the face of obstacles.

- Independence — Job requires developing one’s own ways of doing things, guiding oneself with little or no supervision, and depending on oneself to get things done.

- Leadership — Job requires a willingness to lead, take charge, and offer opinions and direction.

Work Values

- Support — Occupations that satisfy this work value offer supportive management that stands behind employees. Corresponding needs are Company Policies, Supervision: Human Relations and Supervision: Technical.

- Relationships — Occupations that satisfy this work value allow employees to provide service to others and work with co-workers in a friendly non-competitive environment. Corresponding needs are Co-workers, Moral Values, and Social Service.

- Achievement — Occupations that satisfy this work value are results-oriented and allow employees to use their strongest abilities, giving them a feeling of accomplishment. Corresponding needs are Ability Utilization and Achievement.

Performance Measures

Internal Key Performance Indicators (Sources: Internal data collections, and Post-Graduate Surveys)

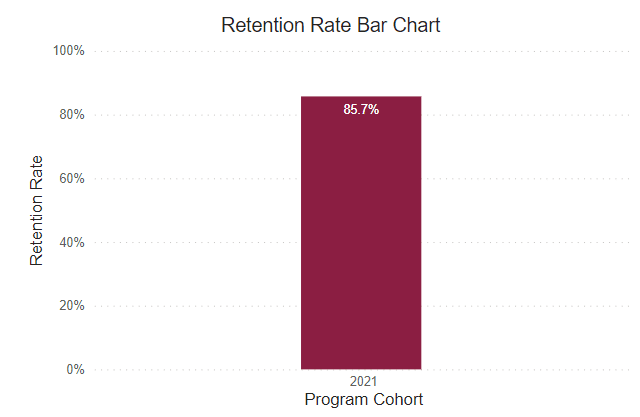

Retention Rate

This rate reflects the continuous term-to-term persistence rate for certificate programs and the fall-to-fall retention rate for associate degree programs.

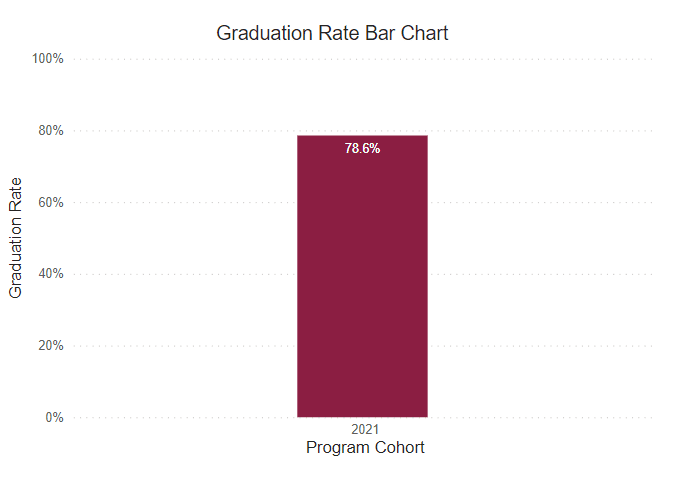

Graduation Rate

This rate reflects the number of freshmen who were officially enrolled in the fall semester and earned a certificate or degree within the expected timeframe.

Our graduates work with the industry’s best