Cabinetmaking & Wood Technology

Get started today

About Cabinetmaking & Wood Technology

Repeated surveys of the woodworking industry have revealed the number one concern facing the industry for the 21st century is the lack of skilled and motivated workers. There is a continual need in the furniture, kitchen cabinet, and architectural millwork industries for persons possessing the skills and knowledge required to produce high quality wood products.

The Cabinetmaking and Wood Technology program is committed to continually providing students with the skills and knowledge required for rewarding jobs in the various woodworking industries. Based upon the belief that students learn best by working on projects, this program is strongly project-oriented.

Hence, students will produce several pieces of fine furniture after which they will further develop and display their skills by producing an advanced wood project of their choosing. Through the use of the College’s housing project, students will learn to list and produce all the millwork items required for a residential house. Additionally, students will design, produce, finish, and install a complete kitchen. Through the use of lectures, demonstrations, and the above projects, the program faculty feels they can best prepare students for careers in any of the three major woodworking fields: fine furniture, architectural millwork, and kitchen cabinetry.

What You’ll Learn

- Identify nomenclature and the proper use of hand and portable power tools.

- Apply the knowledge of wood as a material in the proper construction of various fine furniture projects.

- Demonstrate safe practice in the use and setup of trade machinery.

- Demonstrate skill in the use of drafting equipment in order to produce shop drawings.

- Read shop blueprints to develop accurate material lists.

- Demonstrate knowledge of finishing materials along with the skills required for wood finishing including the following: wood preparation, wood coloring using various stains, and top coating using oil finishes, shellacs, varnishes, and lacquers.

- Demonstrate the ability to list and prepare millwork items required for various building projects.

- Demonstrate proficiency in grinding knives for the shaper and molder and the setup of machines for production.

- Demonstrate the ability to produce jigs and fixtures required for production work.

- Demonstrate the skills and knowledge necessary for kitchen layout, design, construction, and installation.

- Develop the skills and knowledge required for producing various types of countertops.

- Develop a strong work ethic along with the ability to work independently and as a contributing member of a team.

Sample Job Titles

Cabinet Assembler, Cabinet Builder, Cabinet Installer, Cabinetmaker, Double End Tenon Operator, Frame Builder, Framer, Woodworker

Quick facts

Location

Thaddeus Stevens College Main Campus, Snyder Building

Type of program

Associate Degree

Job/Salary Outlook

See industry data

Length of program

2 years, 73 credits

Cost of program

$4,500/semester tuition

$3,000 – $3,500/semester housing

$1,850 – $2,335/semester meal plan

Tool List (PDF)

The outcomes speak for themselves

Finding work directly in commercial or residential construction, this program prepares students to be successful framers, woodworkers, and cabinet builders.

100%

employment

$45K

med. salary

People of TSCT

Success stories

Program details

Courses

MODEL SCHEDULE FOR CABINETMAKING & WOOD TECHNOLOGY

Semester 1

- CABM 106 Hand Tools and Portable Power Tools (4 credits)

- CABM 111 Furniture Construction I (4 credits)

- CABM 117 Finishing I (2 credits)

- CABM 121 Related Drawing I (2 credits)

- MATH 126 Technical Mathematics I (or higher level math) (3 credits)

- CIS 111 Intro to Computer Applications (3 credits)

Semester 2

- CABM 151 Advanced Machinery (3 credits)

- CABM 156 Furniture Construction II (4 credits)

- CABM 162 Finishing II (2 credits)

- CABM 166 Job Management (1 credit)

- CABM 171 Related Drawing II (2 credits)

- CIS 105 Drawing with AutoCAD (3 credits)

- BUSN 106 Small Business Management (3 credits)

- MATH 132 Elementary Geometry (or higher level math) (3 credits)

Semester 3

- CABM 206 Advanced Wood Project (6 credits)

- CABM 211 Machine Maintenance (1 credit)

- CABM 221 Architectural Millwork (4 credits)

- CABM 226 Custom Woodworking Cutters (1 credit)

- ENG 106 English Composition (3 credits

- Science Elective (3 credits)

Semester 4

- CABM 251 Shop Operations and Management (1 credit)

- CABM 261 Kitchen Cabinet Planning & Estimating (3 credits)

- CABM 263 Kitchen Cabinet Construction (4 credits)

- CABM 265 Cabinet Installation (2 credits)

- CABM 267 Counter Top Fabrication (2 credits)

- Humanities General Education Elective (3 credits)

Additional General Education Requirements

- HEAL Elective HEAL 106 or HEAL 111 (1 credit)

- Elective General Studies Elective (3 credits)

Total Credits 73

Faculty

Occupational Advisory Committee

The Occupational Advisory Committee (OAC) serves as a vital link between the Program of study and industry, ensuring that the program remains aligned with current workforce needs, technological advancements, and best practices in the field. Composed of employers, educators, and other community members, the committee provides guidance, feedback, and recommendations to enhance the curriculum, instructional methods, and student learning experiences.

Purpose and Responsibilities:

- Curriculum & Industry Alignment

- Workforce Readiness

- Student & Faculty Support

- Internship & Employment Connections

- Accreditation & Program Evaluation

- Facilities & Equipment Recommendations

By fostering a strong relationship between academia and industry, the OAC helps ensure that Thaddeus Stevens College programs maintain the highest standards in CTE (career and technical education).

- Jonathan Beck, Craftpoint Concepts

- Patrick Kennedy, Superior Woodcraft, Inc.

- Dave Riebe, Kountry Kraft

- Keith Rothermel, QCCI

- Lyndon Sentz, Lyndon Heath Cabinetry

Essential Skills Learned

Tasks

- Verify dimensions or check the quality or fit of pieces to ensure adherence to specifications.

- Produce or assemble components of articles, such as store fixtures, office equipment, cabinets, or high-grade furniture.

- Measure and mark dimensions of parts on paper or lumber stock prior to cutting, following blueprints, to ensure a tight fit and quality product.

- Set up or operate machines, including power saws, jointers, mortisers, tenoners, molders, or shapers, to cut, mold, or shape woodstock or wood substitutes.

- Establish the specifications of articles to be constructed or repaired or plan the methods or operations for shaping or assembling parts, based on blueprints, drawings, diagrams, or oral or written instructions.

- Attach parts or subassemblies together to form completed units, using glue, dowels, nails, screws, or clamps.

- Reinforce joints with nails or other fasteners to prepare articles for finishing.

- Install hardware, such as hinges, handles, catches, or drawer pulls, using hand tools.

- Trim, sand, or scrape surfaces or joints to prepare articles for finishing.

Tools used in this occupation

- Adjustable wrenches — Adjustable hand wrenches

- Augers — Hand augers

- Automatic lathe or chucking machine — Wood lathes

- Awls

- Banders — Edge banders

- Bandsaw wheel — Bandsaws

- Bastard cut file — Bastard flat files

Technology used in this occupation

- Computer-aided design CAD software — Autodesk AutoCAD

- Database user interface and query software — Data entry software

- Electronic mail software — Microsoft Outlook

- Facilities management software — Computerized maintenance management system CMMS

- Operating system software — Microsoft Windows

Knowledge

- Mathematics — Knowledge of arithmetic, algebra, geometry, calculus, statistics, and their applications.

- Building and Construction — Knowledge of materials, methods, and the tools involved in the construction or repair of houses, buildings, or other structures such as highways and roads.

- Production and Processing — Knowledge of raw materials, production processes, quality control, costs, and other techniques for maximizing the effective manufacture and distribution of goods.

- Design — Knowledge of design techniques, tools, and principles involved in the production of precision technical plans, blueprints, drawings, and models.

- Mechanical — Knowledge of machines and tools, including their designs, uses, repair, and maintenance.

Skills

- Operation Monitoring— Watching gauges, dials, or other indicators to make sure a machine is working properly.

- Quality Control Analysis— Conducting tests and inspections of products, services, or processes to evaluate quality or performance.

- Monitoring— Monitoring/Assessing performance of yourself, other individuals, or organizations to make improvements or take corrective action.

- Operation and Control— Controlling operations of equipment or systems.

- Critical Thinking— Using logic and reasoning to identify the strengths and weaknesses of alternative solutions, conclusions, or approaches to problems.

- Equipment Selection— Determining the kind of tools and equipment needed to do a job.

- Judgment and Decision Making— Considering the relative costs and benefits of potential actions to choose the most appropriate one.

Abilities

- Arm-Hand Steadiness — The ability to keep your hand and arm steady while moving your arm or while holding your arm and hand in one position.

- Finger Dexterity — The ability to make precisely coordinated movements of the fingers of one or both hands to grasp, manipulate, or assemble very small objects.

- Manual Dexterity — The ability to quickly move your hand, your hand together with your arm, or your two hands to grasp, manipulate, or assemble objects.

- Near Vision — The ability to see details at close range (within a few feet of the observer).

- Control Precision — The ability to quickly and repeatedly adjust the controls of a machine or a vehicle to exact positions.

- Multilimb Coordination — The ability to coordinate two or more limbs (for example, two arms, two legs, or one leg and one arm) while sitting, standing, or lying down. It does not involve performing the activities while the whole body is in motion.

- Trunk Strength — The ability to use your abdominal and lower back muscles to support part of the body repeatedly or continuously over time without ‘giving out’ or fatiguing.

- Visualization — The ability to imagine how something will look after it is moved around or when its parts are moved or rearranged.

- Problem Sensitivity — The ability to tell when something is wrong or is likely to go wrong. It does not involve solving the problem, only recognizing there is a problem.

Work Activities

- Getting Information — Observing, receiving, and otherwise obtaining information from all relevant sources.

- Controlling Machines and Processes — Using either control mechanisms or direct physical activity to operate machines or processes (not including computers or vehicles).

- Handling and Moving Objects — Using hands and arms in handling, installing, positioning, and moving materials, and manipulating things.

- Performing General Physical Activities — Performing physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling of materials.

- Making Decisions and Solving Problems — Analyzing information and evaluating results to choose the best solution and solve problems.

- Estimating the Quantifiable Characteristics of Products, Events, or Information — Estimating sizes, distances, and quantities; or determining time, costs, resources, or materials needed to perform a work activity.

- Inspecting Equipment, Structures, or Material — Inspecting equipment, structures, or materials to identify the cause of errors or other problems or defects.

- Identifying Objects, Actions, and Events — Identifying information by categorizing, estimating, recognizing differences or similarities, and detecting changes in circumstances or events.

Work Context

- Face-to-Face Discussions — 91% responded “Every day.”

- Wear Common Protective or Safety Equipment such as Safety Shoes, Glasses, Gloves, Hearing Protection, Hard Hats, or Life Jackets — 76% responded “Every day.”

- Spend Time Standing — 76% responded “Continually or almost continually.”

- Indoors, Not Environmentally Controlled — 63% responded “Every day.”

- Spend Time Using Your Hands to Handle, Control, or Feel Objects, Tools, or Controls — 55% responded “Continually or almost continually.”

- Exposed to Hazardous Equipment — 70% responded “Every day.”

- Importance of Being Exact or Accurate — 39% responded “Very important.”

- Time Pressure — 39% responded “Every day.”

- Contact With Others — 52% responded “Constant contact with others.”

Interests

- Realistic — Realistic occupations frequently involve work activities that include practical, hands-on problems and solutions. They often deal with plants, animals, and real-world materials like wood, tools, and machinery. Many of the occupations require working outside and do not involve a lot of paperwork or working closely with others.

- Conventional — Conventional occupations frequently involve following set procedures and routines. These occupations can include working with data and details more than with ideas. Usually, there is a clear line of authority to follow.

Work Styles

- Dependability — Job requires being reliable, responsible, and dependable, and fulfilling obligations.

- Attention to Detail — Job requires being careful about detail and thorough in completing work tasks.

- Cooperation — Job requires being pleasant with others on the job and displaying a good-natured, cooperative attitude.

- Stress Tolerance — Job requires accepting criticism and dealing calmly and effectively with high-stress situations.

- Adaptability/Flexibility — Job requires being open to change (positive or negative) and to considerable variety in the workplace.

- Concern for Others — Job requires being sensitive to others’ needs and feelings and being understanding and helpful on the job.

- Persistence — Job requires persistence in the face of obstacles.

- Self-Control — Job requires maintaining composure, keeping emotions in check, controlling anger, and avoiding aggressive behavior, even in very difficult situations.

- Initiative — Job requires a willingness to take on responsibilities and challenges.

- Integrity — Job requires being honest and ethical.

- Independence — Job requires developing one’s own ways of doing things, guiding oneself with little or no supervision, and depending on oneself to get things done.

- Achievement/Effort — Job requires establishing and maintaining personally challenging achievement goals and exerting effort toward mastering tasks.

Work Values

- Relationships — Occupations that satisfy this work value allow employees to provide service to others and work with co-workers in a friendly non-competitive environment. Corresponding needs are Co-workers, Moral Values, and Social Service.

- Support — Occupations that satisfy this work value offer supportive management that stands behind employees. Corresponding needs are Company Policies, Supervision: Human Relations and Supervision: Technical.

- Achievement — Occupations that satisfy this work value are results-oriented and allow employees to use their strongest abilities, giving them a feeling of accomplishment. Corresponding needs are Ability Utilization and Achievement.

Performance Measures

Internal Key Performance Indicators (Sources: Internal data collections, and Post-Graduate Surveys)

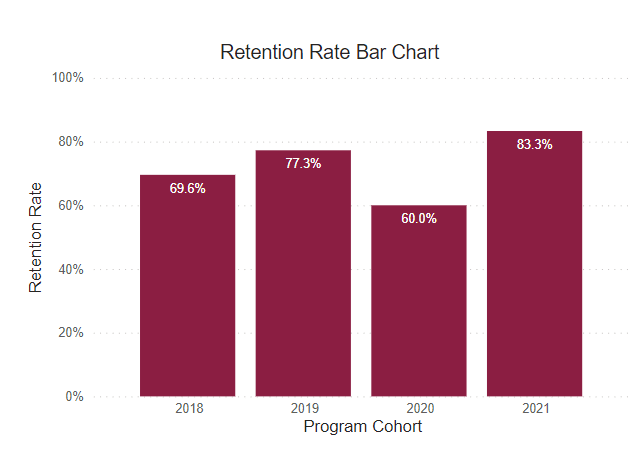

Retention Rate

This rate reflects the continuous term-to-term persistence rate for certificate programs and the fall-to-fall retention rate for associate degree programs.

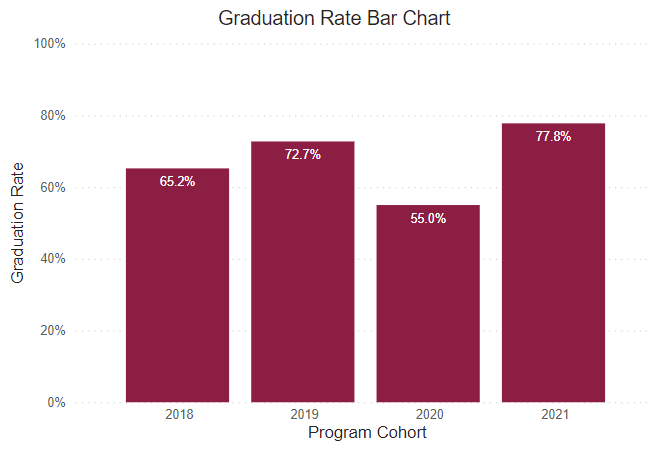

Graduation Rate

This rate reflects the number of freshmen who were officially enrolled in the fall semester and earned a certificate or degree within the expected timeframe.

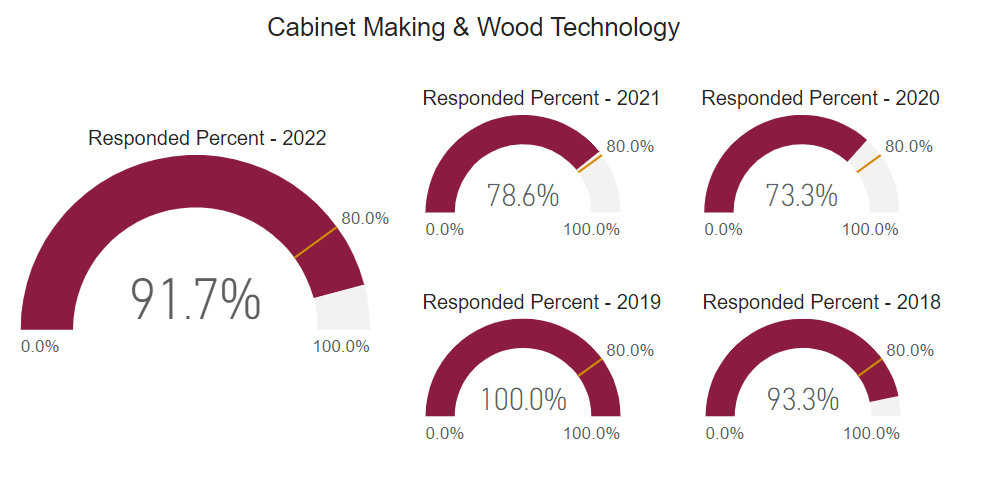

Post Graduate Survey Response Rate

The post graduate survey is an annual on-line post graduate survey utilized by the college to gather vital information regarding career placement, starting salary, and level of satisfaction.

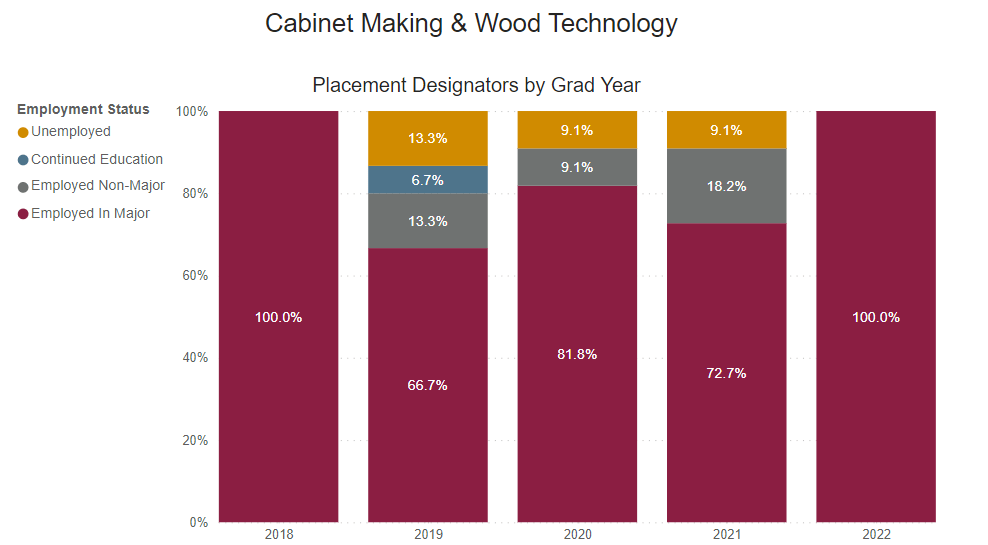

Employed Full Time Outside of Major

Percentage of graduates who reported being employed full-time outside their field of study.

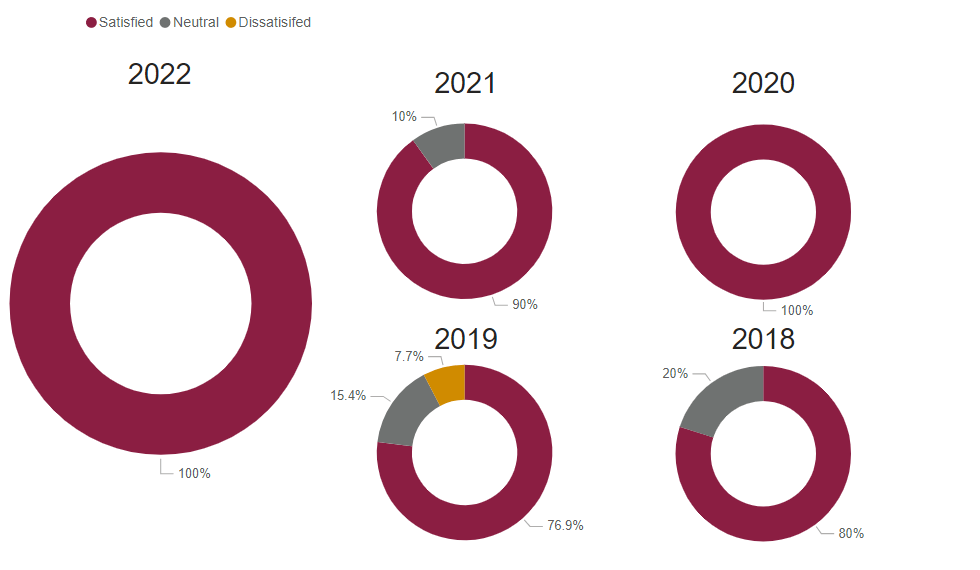

Graduate Satisfaction

This is the median graduate survey response evaluating the level of preparation for workforce entry (based on a 5-Item Likert Scale).

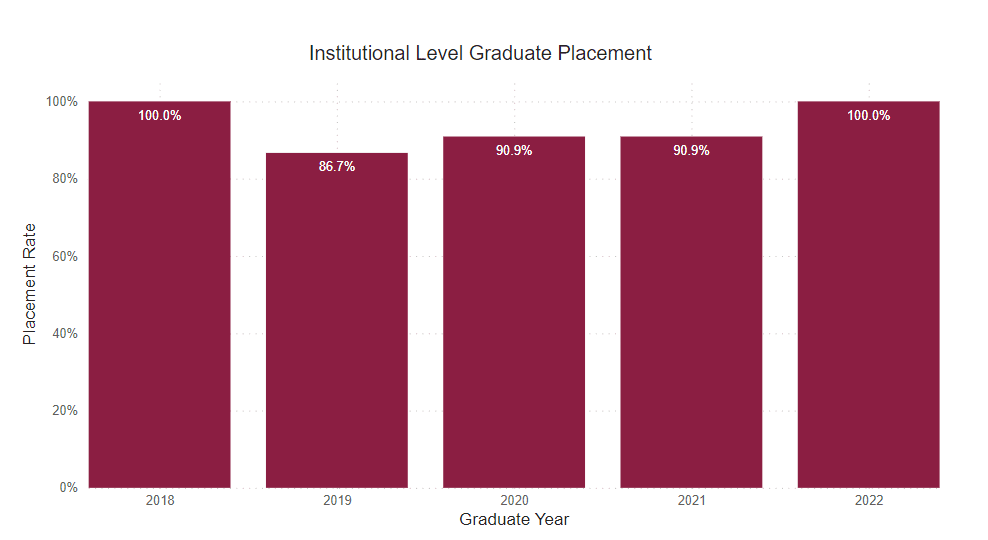

Placement Rate

This is the percent of graduate survey respondents who reported being employed or continued their education on a full-time basis.

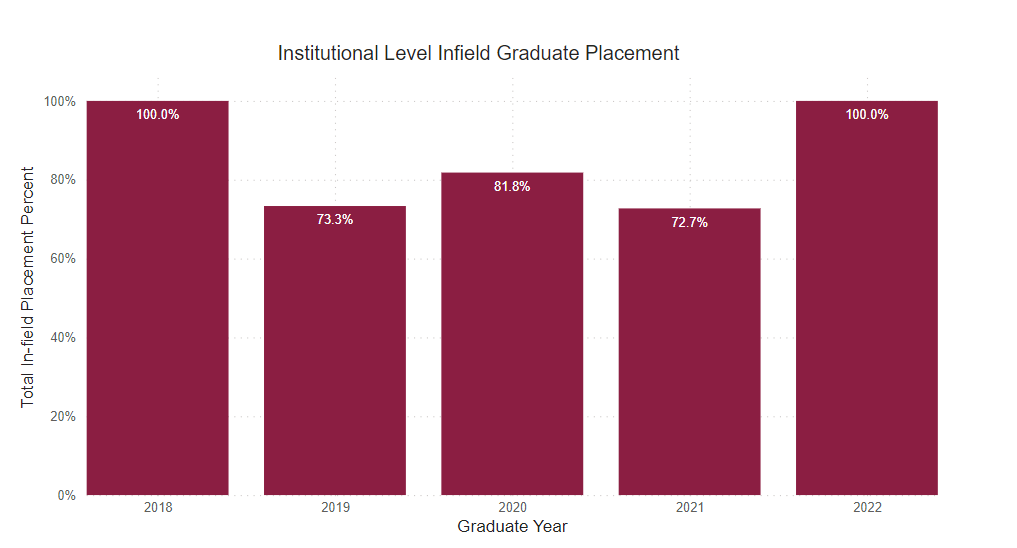

Employed Full Time Within Major

Percentage of graduates who reported being employed full-time within their field of study.

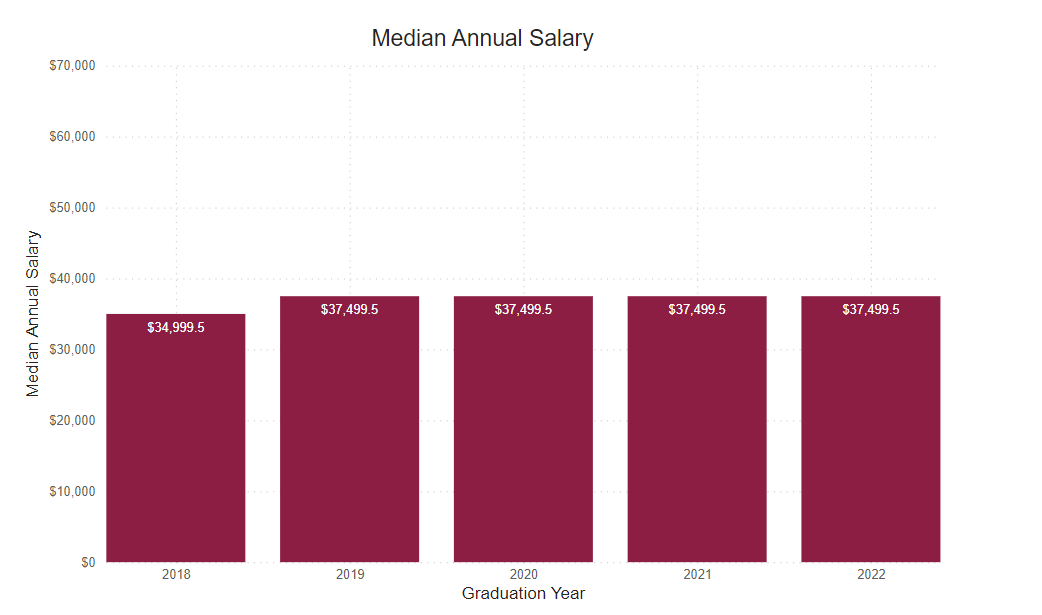

Annual Median Starting Salary

This number is based on the graduate survey response to the request to identify a starting salary from a range of options. This graph shows the median first-year annual salary. All calculations are based on the respondent’s self-reported first-year annual income.

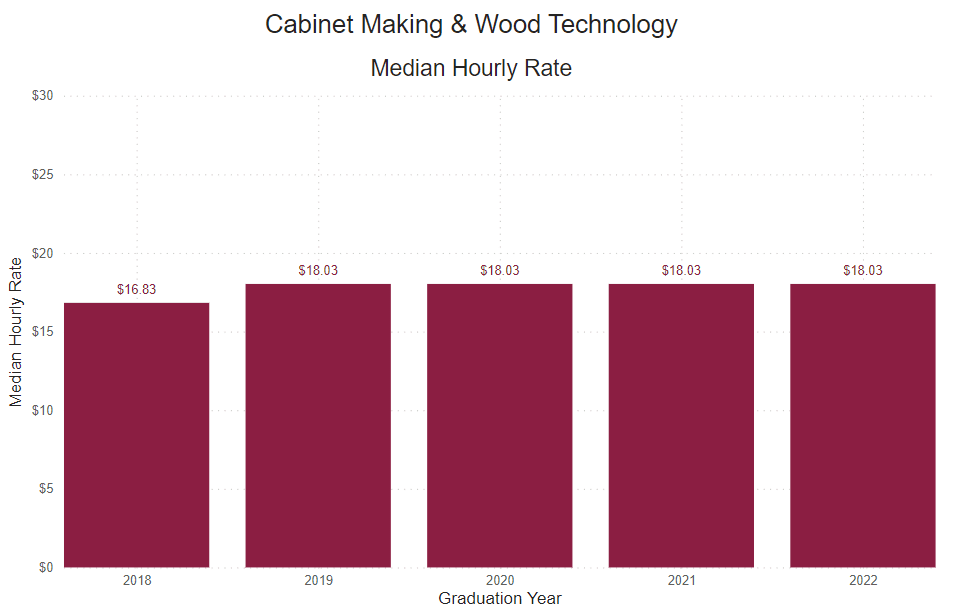

Reported Hourly Rate

This number is determined by dividing the reported median salary by the number of hours in a traditional full-time work week (40), then the number of weeks in a year (52).

Our graduates work with the industry’s best